Hanyar kalandar bene na PVC hanya ce mai inganci da ci gaba da samarwa, wacce ta dace musamman don samar da zanen gado mai kama da juna (kamar shimfidar bene mai kama da kasuwanci). Babban sa shine a sanya narkakkarwar PVC ta zama sirara iri ɗaya ta hanyar calender multiroll, sannan a sanyaya shi ya siffata. Wadannan su ne takamaiman matakai da mahimman wuraren sarrafa fasaha:

I. Tsarin Kalanda

Raw Material Pretreatment > Haɗin zafi mai sauri, sanyaya da gaurayawan sanyi, hadawa na ciki da filastik, hadawa da buɗewa da ciyarwa

Calendering-bidi-bidi, embossing/laminating, sanyaya da siffata, datsa da iska

II. Mataki-mataki Mahimman Abubuwan Ayyuka da Ma'auni na Fasaha

1. Raw Material Pretreatment da Mix

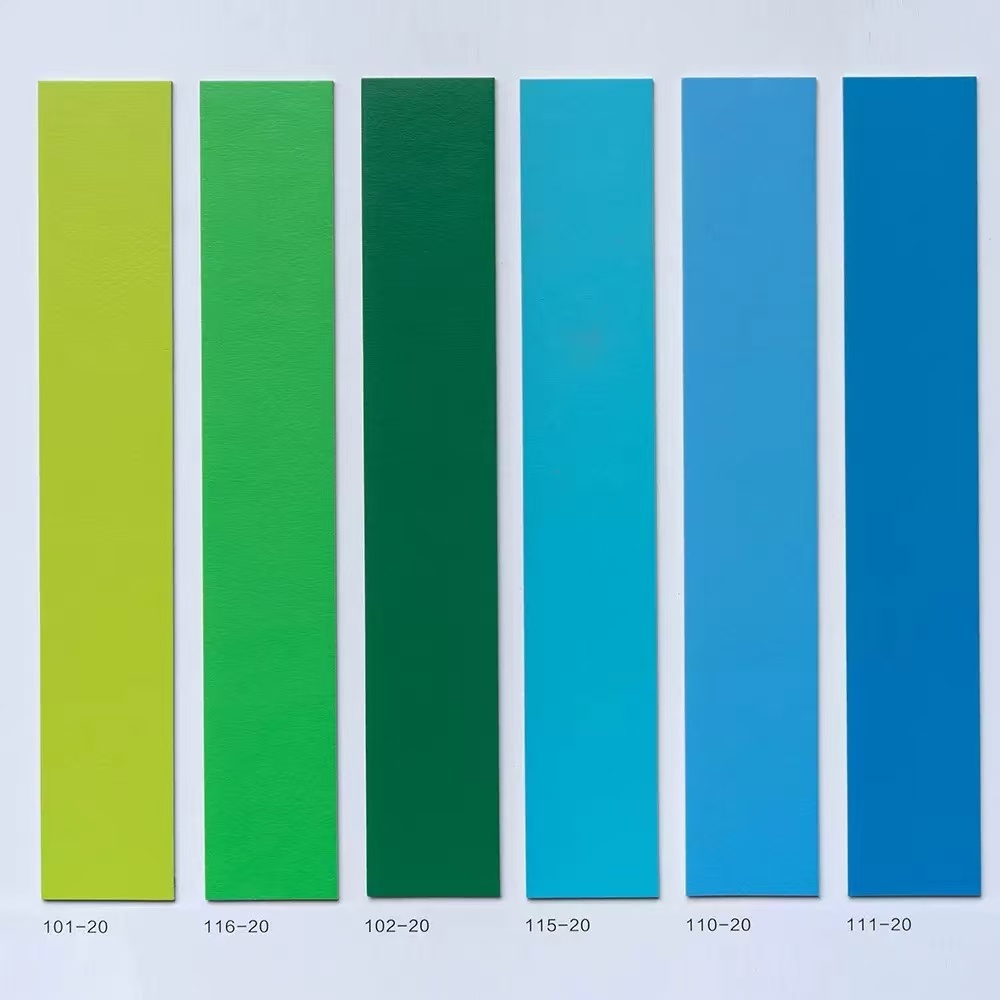

Tsarin Formula (Misali): - PVC guduro (nau'in S-70) 100 sassa, - Plasticizer (DINP / ester muhalli abokantaka) 40-60 sassa, - Calcium carbonate filler (1250 raga) 50-80 sassa, - Heat stabilizer (calcium zinc composite), - 3-5-cant acid part, - 3-5-cant acid - Pigment (titanium dioxide / inorganic launi foda) 2-10 sassa

Tsarin Haɗawa*:

Haɗin zafi: Mai haɗawa mai sauri (≥1000 rpm), zafi zuwa 120 ° C (minti 10-15) don ba da damar PVC don ɗaukar filastik; Cold Cakuda: Da sauri sanyi zuwa ƙasa da 40°C (don hana kumburi), lokacin haɗawar sanyi ≤ 8 mintuna.

2. Filastik da Ciyarwa

- Mixer na ciki: Zazzabi 160-170 ° C, Matsi 12-15 MPa, Lokaci 4-6 mintuna → Samar da tarin roba mai kama da juna;

Buɗe Mixer: Twin-roll zazzabi 165±5°C, Roller Gap 3-5 mm → Yanke cikin tube don ci gaba da ciyarwa zuwa calender.

3. Kalandar nadi-hudu (Tsarin Tsari)

- Mabuɗin Dabaru:

- Girman Matsala: 1 #: 2 #: 3 #: 4 # = 1: 1.1: 1.05: 1.0 (don hana tarin kayan aiki);

- Tsakanin Tsawon Tsayi: An tsara Roller 2 tare da kambi na 0.02-0.05mm don daidaita nakasar lankwasawa ta thermal. 4. Maganin Sama da Lamination

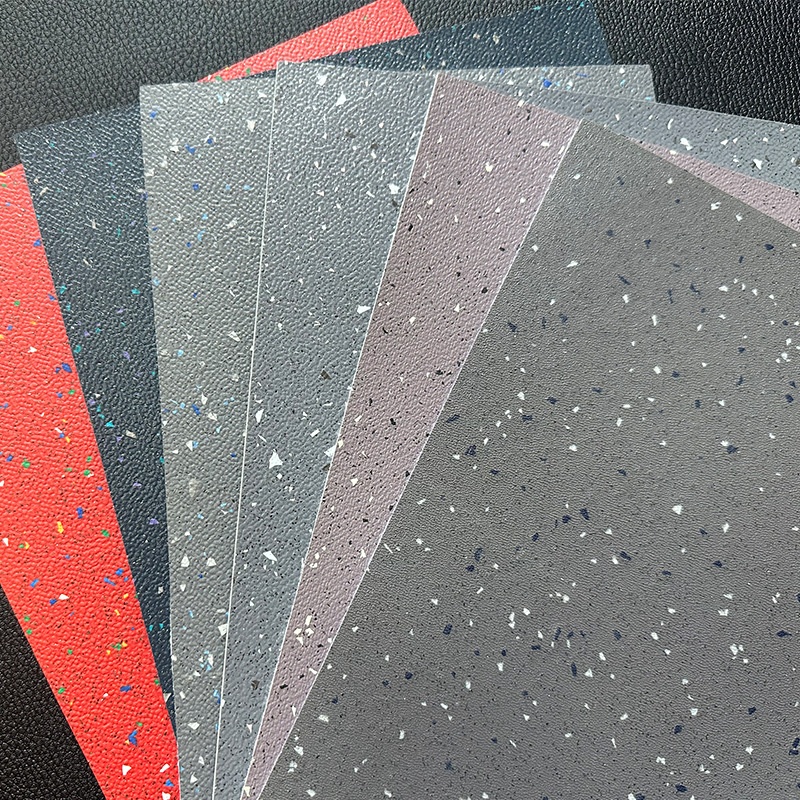

Embossing: Embossing abin nadi (silicone / karfe) zafin jiki 140-150 ° C, matsa lamba 0.5-1.0 MPa, gudun dace da calendering line;

Substrate Lamination (ZABI): Gilashin fiber mat/ masana'anta mara saƙa, preheated (100°C), an lulluɓe shi tare da narke PVC a abin nadi #3 don haɓaka kwanciyar hankali.

5. Sanyaya da Siffata

Zazzabi mai sanyaya mai hawa uku:

Sarrafa tashin hankali: Tashin hankali 10-15 N/mm² (don hana sanyin sanyi da nakasa).

6. Gyara da Iska

- Laser Ma'aunin Kauri akan Layi: Amsa na ainihi yana daidaita tazarar abin nadi (daidai ± 0.01mm);

- Gyara ta atomatik: Nisa ≤ 20mm, sake yin fa'ida da pelletized don sake amfani;

- Winding: Ci gaba da tashin hankali cibiyar winding, yi diamita Φ800-1200mm. III. Tsari Wahalhalu da Magani

1. Rashin Kauri. Dalili: Canjin Zazzabi na Roller> ± 2°C. Magani: Rufe-Madauki Sarrafar Zazzaɓin Mai Mai zafi + Cooling Nadi Mai Rufewa.

2. Gas na saman. Dalili: Rashin Isasshen Hadawa Degassing. Magani: Vacuum the Internal Mixer (-0.08 MPa).

3. Matsalolin Gefe. Dalili: Yawan Yin Sanyi/Tsarin Tashi. Magani: Rage Ƙarshen sanyi na Gaba-Ƙarshen kuma Ƙara Yanki mai Sanyi a hankali.

4. Tsarin Mutuwa. Dalili: Rashin isassun Matsalolin Nadi. Magani: Ƙara Matsi na na'ura mai aiki da karfin ruwa zuwa 1.2 MPa kuma Tsaftace saman Nadi.

IV. Abokan Muhalli da Tsarukan Inganta Ayyuka

1. Maye gurbin Stabilizer-Free-Lead:

Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Ya wuce EN 14372 Gwajin Hijira;

2. Filastik Mai Kyautar Muhalli:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Yana Rage Ecotoxicity.

3. Sake amfani da sharar gida:

- Crushing scraps → Haɗuwa da sabon abu a cikin rabo na ≤30% → Ana amfani da shi wajen samar da tushe.

V. Kalanda vs. Extrusion (kwatancen aikace-aikacen)

Tsarin Samfuri: Tsarin shimfidar ƙasa mai kauri mai kauri/Maɗaukaki mai nau'i-nau'i, haɗaɗɗen haɗin gwiwa mai yawa (Layer mai jure sawa + Layer kumfa)

Tsawon Kauri: 1.5-4.0mm (Daidai ± 0.1mm), 3.0-8.0mm (Daidai ± 0.3mm)

Ƙarshen saman: Babban mai sheki/Madaidaicin embossing (kwaikwayon hatsin itace), Matte/Rough texture

Aikace-aikace na yau da kullun: Tsarin bene mai kama da juna a asibitoci da dakunan gwaje-gwaje, shimfidar bene na SPC don gidaje

Takaitawa: Babban darajar hanyar calending ta ta'allaka ne a cikin "madaidaici mai girma" da "madaidaicin daidaituwa"

- Amfanin Tsari:

- Madaidaicin abin nadi na zafin jiki → Matsakaicin bambancin kauri <1.5%;

- In-line embossing da lamination → Cimma tasirin gani na dutse / ƙarfe;

- Samfuran da ake buƙata:

Filayen PVC masu kama da juna tare da buƙatun kwanciyar hankali mai girma (kamar jerin Tarkett Omnisports);

- Zaɓuɓɓukan haɓakawa:

- Gudanar da hankali: daidaitawar gibin abin nadi mai ƙarfi mai ƙarfi AI (maganin kauri na ainihi);

- Farfadowar Makamashi: Ana amfani da zafin sharar ruwa mai sanyaya don dumama albarkatun ƙasa (ajiye 30% makamashi).

> Lura: A cikin ainihin samarwa, ya kamata a daidaita zafin jiki na calending da saurin abin nadi bisa ga ma'anar ruwa (narkewar MFI = 3-8g / 10min) don guje wa lalacewa (ƙididdigar rawaya ΔYI <2).

Lokacin aikawa: Yuli-30-2025